CATHODIC PROTECTION (CP) SERVICES

CATHODIC PROTECTION (CP) SERVICES

Previous

Next

CATHODIC PROTECTION (CP) SERVICES

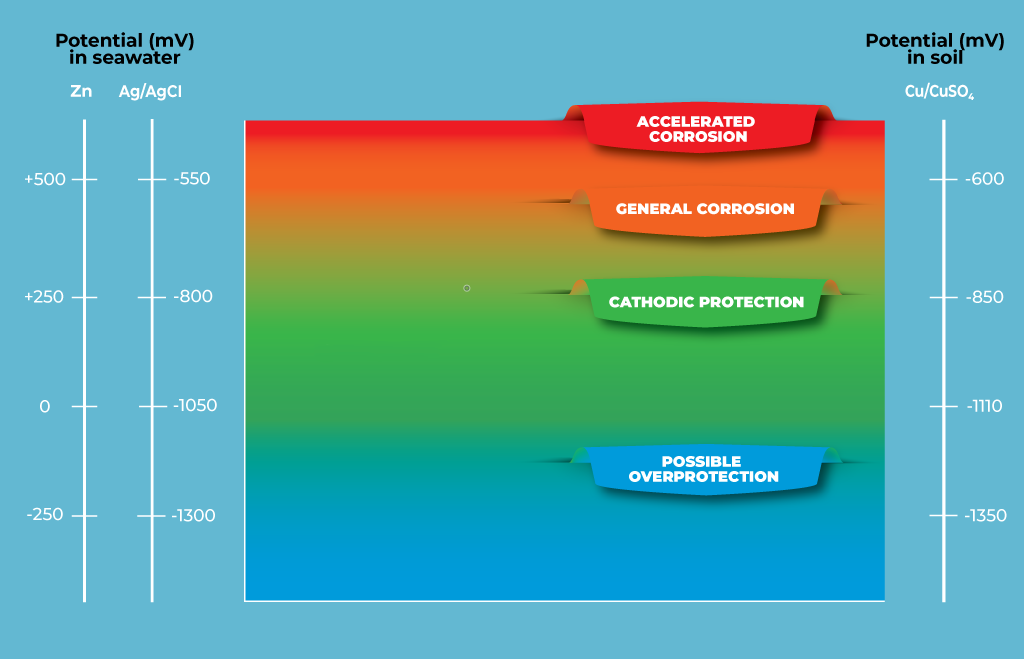

To prevent corrosion from damaging and tearing down valuable assets, cathodic protection systems are installed. Our CP support team has more than 20 years of experience within cathodic protection and offers various types of solutions. We provide a wide range of cathodic protection(CP) services and solutions that prevent and control corrosion as apart of integrity management of fixed platforms, including:

- CP modeling and design

- CP inspection Management, Our combination of practical and theoretical approaches provides more accurate results, which is essential when considering inspection intervals and life extension studies.

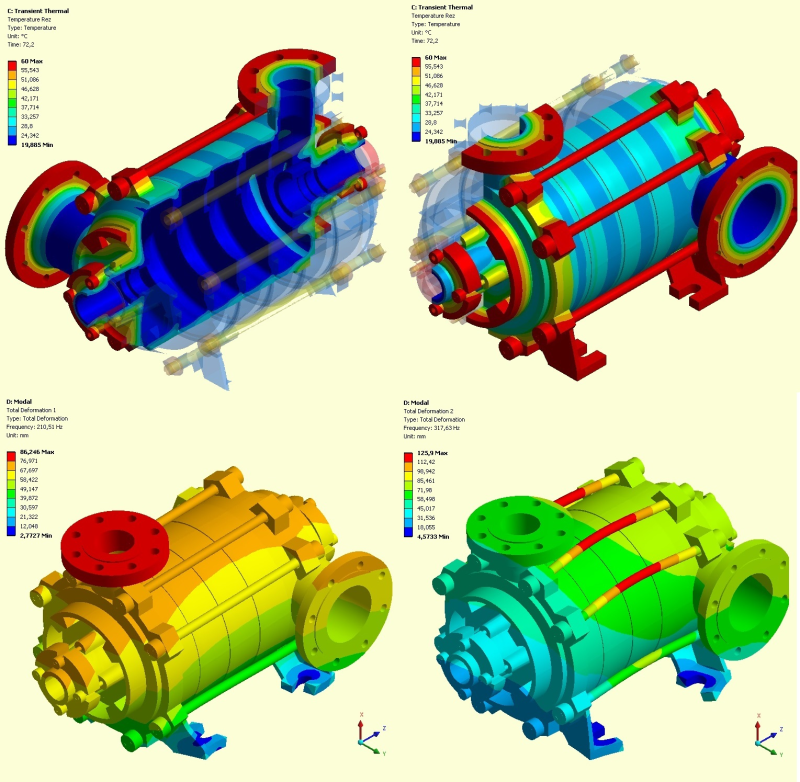

CP MODELLING & DESIGN

We provide cathodic protection modeling of all types of structures and pipelines. Our experts use software solution which can be used to simulate a wide range of designs. The main objective of CP modeling is to demonstrate the actual performance of a CP system. We affect CP performance throughout its service life on structures, with or without coating, using sacrificial anodes, impressed current and hybrid systems, as well as a unique database with real-life data to simulate the exact amount of retrofit anodes needed for retrofitting and life extension. This comprehensive approach gives us a competitive edge regarding the quality and reliability of our CP modeling results. We can demonstrate considerable savings by using real-life current densities as opposed to conservative design codes. We can also verify CP designs using design code values. Typical cases evaluated by CP modeling:

- Current shadow effects, current drain, and anode distribution issue.

- Uneven anode consumption.

- Over or under-protection.

- Protection in confined areas, small annuluses, etc.

- Galvanic corrosion

- Anode interference

- Interaction between connected structures

- Pipeline attenuation. With CP modelling, you can try out different scenarios in order to ensure the optimal protection of your asset. Our services within CP design include:

- Traditional CP design with both impressed current and sacrificial anodes

- CP design verification

- CP retro fit design

- Anode protection range and attenuation calculations

- CP design of stainless steels (see RCP further down)

- Material compatibility with cathodic protection systems

CP INSPECTION MANAGEMENT

Detailed design specifications for installing sacrificial and impressed current systems, maintenance, and repair recommendations for Conventional and Deep anode ground beds, Monitoring program development (including Anode life and efficiency, current rating audit, and requirements).

Experience shows that placing a qualified owner’s representative at the construction site during the project can significantly impact the final success of the project. Quad is an authorized inspection and asset integrity company. We can support your QA inspectors and plant engineers with new-build and In-service inspectors and ensure your pressure equipment meet all safety regulations as per the governing authority. Our representative can act as:

- Owner’s representative direct reference to end user, serving only one “master”

- Process (welding, NDE and coating) specialist surveyor–monitoring craftsmanship, better quality

- First-hand monitoring of progress–any delays can be identified early, and action initiated without delay

- Flexible resource–man up/down according to project intensity. The quality of the entire delivery depends on numerous factors:

- Design quality

- Specification detail

- Communication between designer, owner, workshop, and classification body

- Experience and attitude of workshop

- “Enforcement” of procedures and specifications.

SOIL CORROSIVITY ANALYSIS

- Soil resistivity, pH, sulfate/chloride content, bacteria, Redox Potential assessments, and indicators of anaerobic conditions.

- Determination of the environment’s corrosivity and make recommendations on the type of corrosion prevention techniques to utilize.

- Using certified labs, soil samples are analyzed for various constituents.

- that contribute to a corrosive environment

STRUCTURE - TO - ELECTROLYTE POTENTIAL SURVEYS

- Assessment and performance evaluation of existing corrosion prevention

- Systems to determine compliance with regulatory requirements.

- AC/DC Interference analysis. Performing troubleshooting techniques to determine if interference conditions exist and make recommendations to mitigate the effects.

- DCVG & ACVG, Close Interval Surveys, Interrupted Potentials

COMMISSIONING & ACCEPTANCE TESTING

- Performing initial energization tests on newly installed corrosion prevention systems.

- Structure/coating non-destructive integrity inspection and evaluation.

- Detailed reports on the status of your corrosion control systems, including detailed solutions to any issues

DESIGN OF CORROSION PREVENTION SYSTEMS

- Design of Corrosion Prevention Systems, Details, Specification compliant with the latest regulatory and industry standards (NACE International/ISO/USEPA/USDOT).

- Design Engineering Oversight of installation and construction activities.

- Designs are performed by NACE Certified CP4s (Cathodic Protection Specialists) with Professional Engineering Licenses in the local jurisdiction.